vickers hardness test case study|rockwell hardness tester procedure pdf : specialty store 1.1 Vickers Hardness. The Vickers test employs a square-based pyramid with . WEBScary Granny House. Clown Nights. Space Bubbles. Geometry neon dash world 2. Zombie Road. Slendrina Must Die The House. Mad Day Special. Friv Legend - Play the 101 .

{plog:ftitle_list}

webReport User. See Lauren Cat's porn videos and official profile, only on Pornhub. Check out the best videos, photos, gifs and playlists from amateur model Lauren Cat. Browse through the content she uploaded herself on her verified profile. Pornhub's amateur model community is here to please your kinkiest fantasies.

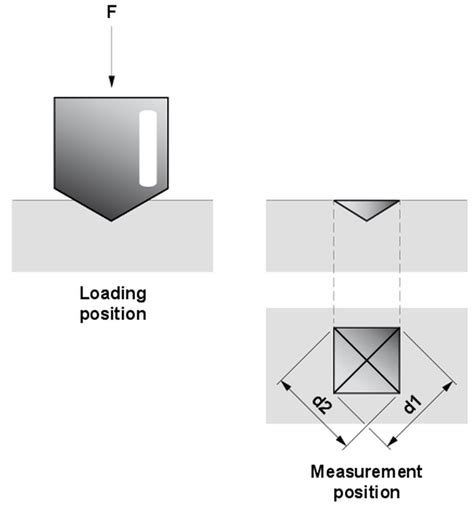

The Vickers hardness test or the 136 degree diamond pyramid hardness test is a microindentation method. The indenter produces a square indentation, the diagonals of which are measured. Vickers hardness number (VHN) can be found directly from the Vickers hardness .1.1 Vickers Hardness. The Vickers test employs a square-based pyramid with . Vickers hardness testing is one of the most useful methods to determine the hardness of materials. To calculate the hardness of materials, the key is to measure the diagonal length of the.

On this page, you can find a description of the Vickers hardness test, practical information on how to apply it and a list of our micro hardness testing machines for Vickers. The Vickers hardness test at a glance: Ideal for micro hardness .

The Vickers hardness test is an extremely useful tool for materials characterization and many manufacturers depend on it as a quality control method. Eliminating the most common error in the test method—operator . This study focuses on the hardness measurement using the Vickers hardness scale and the related uncertainty evaluation using two different methods—law of propagation .

Three-dimensional finite element-based numerical analysis of Vickers indenter hardness test was conducted to investigate the effect of frictional conditions and material anisotropy on.

1.1 Vickers Hardness. The Vickers test employs a square-based pyramid with an angle of 136° between opposing faces. The Vickers hardness is defined as the applied load P divided by the .A method that can be used for figuring out a material’s hardness—a measurement of its resistance to deformation in the presence of force—is the Vickers hardness test. While it finds .The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid Number ( HV ) .

The Vickers method has a test load range from 1 gf according to ISO respectively from 1 gf up to 120 kgf according to ASTM, which means that this method can be used for hardness testing across all load ranges (from the micro to the low .The Vickers Hardness Testing is a cornerstone technique for evaluating the hardness of assorted materials, mainly metals and their types. Formulated in 1921 as a simpler recourse to the Brinell test, it estimates a material’s resistance to deformation under a consistent burden.A vickers hardness testing in the case study has its own reference standard, namely ISO 6507-2: 2018 Metal material - Hardness Test Verification and Calibration of the test machine. The vickers hardness test equipment is a machine to conduct tests using a diamond pyramid with a plane angle of 136°, by means of an emphasis by an indentor that .

Hardness of the samples has been evaluated by using Vickers Hardness Test. The Corrosion behaviour of as-received and thermally oxidised samples have been evaluated by using weight loss method. 1. Introduction. Hardness testing, defined as a test method to measure a material’s resistance to permanent indentation, was developed for metals but can be applied to polymers even though they exhibit a viscoelastic response that complicates the analysis [1,2].However, it is only after appropriate calibration and parameter selection that hardness . Vickers hardness test uses a very small diamond indenter with a pyramidal geometry that has an angle of 136 \(^\circ\) between the plane faces of the indenter tip. The Vickers hardness measurement .

The Vickers Hardness test (ISO 6507) is used to characterize hardness of various solid materials (metals, ceramics, etc.). A diamond pyramid is pressed against the solid with a certain normal load and the hardness is calculated based on the imprint left on the surface. . HIGHLIGHTS • A new study details . Guidance Notes on Friction 19.03. . 6.1 Case Study: HV1. A hardness block of Vickers scale HV1 has been investigated. The hardness block was calibrated in the primary hardness machine in the HV1 scale following the standard procedure. Since the Vickers hardness scale is HV1, the test force applied was 1 kgf.

The ideal d / D ratio (d = impression diameter, D = ball diameter) for a spherical indenter is 0.375. If tangents are drawn to the ball at the impression edges for d / D = 0.375, they meet below the center of the impression at an angle of 136 degrees, the angle chosen for the Vickers indenter.. Diamond allows the Vickers test to evaluate any material and, furthermore, has the very . Micro Vickers Hardness Testing . The Micro Vickers hardness test uses a traditional Vickers type indenter, but at a microscopic scale. This indenter is a square-pyramidal shape and is typically pressed into the surface of the material for 10-12 seconds. The amount of force used is specified by the operator and varies depending on the materials .UNCERTAINTIES OF VICKERS HARDNESS TEST BLOCKS Robert A. Ellis David L. Ellis Co. Inc., Acton, MA, USA . uncertainty of the Vickers test. It can be shown in some cases that the reference uncertainty is larger than the . The basis of this study is comprised of data from over 300 reference blocks calibrated in less than a year. TheThe DuraScan series is your efficient laboratory companion in the low load and micro hardness range. The standard load range of 10 gf up to 62.5 kgf is applied with a closed loop and can optionally be extended to 0.25 gf up to 62.5 kgf.In addition to Vickers hardness testing—the most commonly used test method—the DuraScan low load and micro hardness testing machines .

Test & Inspection Case Study Hardness Testing Assures Quality in Advanced Materials . and the Vickers hardness test. These three tests measure hardness by determining resistance to the penetration of a non-deformable ball, cone, or four-sided pyramidal indenter. While the Rockwell and Brinell tests apply primarily to bulk metals and ceramics .From the single Vickers test point to fully automatic CHD (case hardness depth) testing . At the end of your measurement, you will find complete lists and a graphical hardness gradient of your test points. User management DuraScan 10/20. By playing this video, you agree to the use of cookies as well as to the transfer of data to YouTube in .The Vickers hardness test, developed in 1921 by Robert L. Smith and George E. Sandland of Vickers Ltd., provides an alternative to the Brinell hardness test with a simpler scale. While it can be used to test the hardness of metals and other hard materials, its main focus is on assessing the ability of softer materials, such as plastics , to .

Browse a few of our case stories to understand the challenges and how our experts and solutions helped solve our customers. . For the Vickers hardness test, the measured diagonals should not deviate more than 5.0% from each other. For the Knoop hardness test, the two halves of the long diagonals must not differ by more than 10.0% from each . The accuracy of the hardness and Young’s modulus results, obtained with Eqs. (1), (2), (3), depends on the evaluation of contact area and compliance.In this study, the contact area, A, was evaluated using the contour of the indentation (see next section).Using this approach, contact area results are independent of the formation of pile-up and sink-in. The Vickers hardness test is a versatile method to measure material hardness in practice. In this study, a comparison of cut-edge hardness between the thermal and mechanical cutting processes was performed on the structural steels S355 and S1100 by using the Vickers hardness test method with a small angle at cut edges to widen the heat-affected .

In the case of Vickers microhardness testing, a highly . load-applying device, and a data processing and display unit. During a scratch hardness test, at a chosen constant load, the stylus is allowed to plow into the test specimen up to a predetermined distance to form a groove. . In this case, the study was based on the increment of .Vickers Hardness Test. The Vickers hardness test utilises a diamond pyramid-shaped indenter to create a small impression on the material's surface. Taking into consideration the weight of the load, the size of the indentation is measured using a microscope. The Vickers hardness number (HV) is calculated based on the indentation diagonal lengths.

In this work we will focus on Vickers hardness, which is one of the most popular techniques given that it is experimentally easy to calculate and can be used for all materials regardless of hardness. Vickers hardness test uses a very small diamond indenter with a pyramidal geometry that has an angle of 136 ∘ between the plane faces of the .The Vickers hardness test plays a pivotal role in material analysis. It’s a reliable method for determining material strength and durability. . Case Studies and Applications. Analogue Vickers hardness testers have been successful in various industries. Their versatility is commendable, from metallurgy to quality control. Instrumented indentation test, also known as nanoindentation test, has been widely used to evaluate the local indentation hardness of materials at the nano- and micro-scales for academic and industrial purposes; it has been frequently compared with the Vickers hardness (HV) test used on larger scales [].A considerable number of studies have . Hardness is a useful measure of a material’s resistance to permanent indentation; but for viscoelastic polymers, hardness data are highly dependent on the test type and the parameter set chosen. Vickers microhardness testing is used to leave small indents (<150 µm) and is shown to be applicable to polymers. A detailed investigation of the required steps for .

The newly developed method was subsequently utilised in two case studies to determine the real hardness properties of sliding worn surfaces and the subsurface hardness profile. . The Vickers hardness test was developed in the 1920′s, in which a square-based pyramid diamond indenter was designed to have specific geometrical configurations .The Vickers hardness test uses a 136° pyramidal diamond indenter that forms a square indent. . The general principle of the Rockwell hardness test in all cases is to compare the depth of indentation under a low preload with the subsequent indentation under a full load. . The objective of the present study is to elucidate the effects of . Variants on the Rockwell hardness test procedure are used depending on the material and strength of a part. . A relatively light, 15 kgf load is applied to case hardened parts treated to achieve a minimum effective case depth 0.007 inches or a total case of 0.012 inches. Other Rockwell variants (HR30N and HR45N) apply slightly higher loads on .

vickers hardness test procedure pdf

Vickers number 1 2 Average 1 0 0 0 312. 2 0 0 0 315. 3 0 0 0 317. 4 0 0 0 292. ANALYSIS Hardness Value: A measurement of the material's hardness is provided by the test's Vickers hardness number. Greater hardness is indicated by a higher HV. Vickers hardness values are a useful tool for comparing the hardness of various materials .

vickers hardness test manual

rockwell hardness tester procedure pdf

Catalogo completo de acompanhantes de Uberaba (MG) Veja as garotas de programa em Uberaba (MG) que ficaram on-line recentemente. Milena, 25 anos. R$150. Mercês. Mercês - 34998052837 - R$150. AYLA DIAS, 27 anos.

vickers hardness test case study|rockwell hardness tester procedure pdf